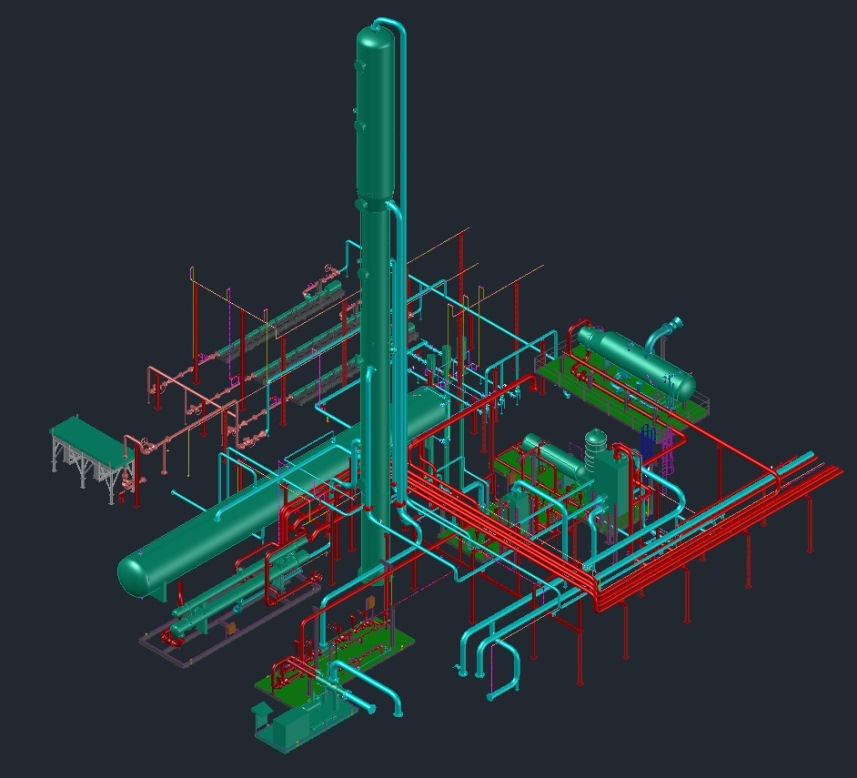

Cryogenic Gas and Turbo Expander Plants

Our cryogenic gas or turbo expander plants help improve project economics by delivering custom engineered solutions with competitive pricing to off-the-shelf designs (from contract to start-up). BCCK’s cryo plant solutions and proven process designs are specifically tailored for your specific project. As a result, our process will result in higher efficiencies, greater recoveries, and more operating flexibility across a wide range of inlet gas flow rates and concentrations than pre-engineered solutions.

Gas Processing Facilities Built for Optimized Efficiency

BCCK can provide custom designs, our C2R-Flex optimized design, or more industry standard process designs in order to meet our customer’s needs. The advantage of BCCK is optimized recoveries (whether that be ethane rejection, recovery or both) and well-integrated and efficient facilities.

In addition to custom designed turbo expander plants and the associated cryogenic gas advantages, BCCK also can offer custom designed results with a quicker delivery and lower costs by utilizing previous turbo expander plant designs for your project. Our previous cryogenic plant designs all process rich associated gas that would match almost any associated gas NGL extraction project. We can utilize near 100 percent of the previous design or make modifications per your specific requirements.

Cryogenic Gas Plant Projects

- 225 MMSCFD C2R-Flex

- 225 MMSCFD RSV

- 100 MMSCFD RSV

- 60 MMSCFD GSP

- 75 MMSCFD GSP

- 100 MMSCFD RSV

- 60 MMSCFD RSV

G2R-Flex™

Premium propane recovery with next-generation technology.

CRYOGENIC GAS & TURBO EXPANDER PLANT SOLUTIONS

Read more about BCCK’s extensive experience in this arena.

C2R-Flex Technology

BCCK has developed a NGL extraction process that allows for maximum margins for the producer. If the recovered component of ethane is negative in value when sold as a liquid product as compared to the BTU value of ethane, then the producer will want to minimize the recovered ethane component while maximizing the propane and heavier components.

BCCK’s patented technology, C2R-Flex, will accomplish this. If the ethane component has a positive spread value when sold as liquid, then the producer will want to maximize the recovered ethane in the NGL liquid.

BCCK’s C2R-Flex technology can effectively operate in three operating modes:

- High ethane recovery of 98% + ethane and near 100% of all heavier products

- Minimum ethane recovery of less than 5% and 98+ % for propane using auxiliary propane refrigeration

- Minimum ethane recovery of less than 5% and 98+ % for propane without using auxiliary propane refrigeration. Note that this option will require additional residue compression.

One significant advantage for C2R-Flex is that the operation mode between ethane recovery and ethane rejection can be accomplished quickly and without facility outage. This option will allow for frequent operational mode changes, if desired, assuring maximum profitability.

Additional Technology Offerings

- NiTech® nitrogen rejection

- Helium recovery

- CO2 removal

- TEG dehydration

- Mole sieve dehydration

- Propane refrigeration

- Inlet gas chilling or dew point suppression

- Condensate separation/stabilization

- Flare systems

- Product storage

- Inlet separation and metering

- Compression

- NGL product fractionation

- MCC’s and electrical power distribution

- PLC and DCS control systems