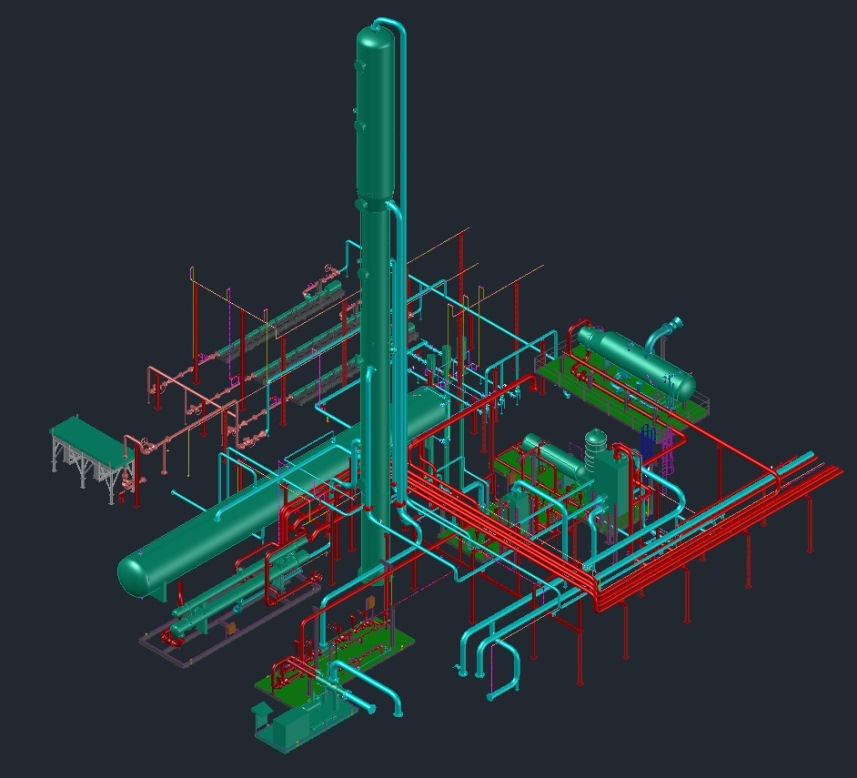

Cryogenic Gas and Turbo Expander Plants

Our cryogenic gas or turbo expander plants help improve project economics by delivering engineered solutions with competitive pricing (from contract to start-up). BCCK’s cryo plant solutions and proven process designs are tailored for your specific project. As a result, our process will result in higher efficiencies, greater recoveries, and offer more operating flexibility across a wide range of inlet gas flow rates and concentrations than pre-engineered solutions.

Why Choose BCCK for Your Cryo Plant?

BCCK offers a seamless process from design to start-up, delivering plants that ensure:

- Higher Efficiency: BCCK systems operate with optimized energy usage, supporting cost reduction and performance enhancement.

- Greater Recoveries: Our cryo plants ensure high recovery rates, including up to 98% ethane and 100% propane and heavier hydrocarbons.

- Operational Flexibility: Tailor your cryogenic system to meet your specific inlet gas flow rates and concentrations.

Key Features of BCCK’s Cryo Plant Solutions

Advanced Technology for Optimized Gas Processing Facilities

BCCK has developed a NGL extraction process that allows for maximum margins for the producer. If ethane is negative in value when sold as a liquid versus a gas, then the producer will want to minimize the recovered ethane while maximizing the propane and heavier components.

If the ethane component has a positive spread value when sold as liquid, then the producer will want to maximize the recovered ethane in the NGL liquid.

Design Capabilities

BCCK can provide custom or more industry standard process designs, such as GSP or RSV, to meet a customer’s needs. The advantage of BCCK is optimized recoveries in ethane rejection or recovery, and well-integrated and efficient facilities.

Applications of Cryogenic Gas Plants

BCCK’s cryo plants support several gas processing functionalities:

- Ethane Recovery & Rejection: Precisely adjust ethane recovery levels depending on market demands.

- NGL Cryo Plants: Maximize NGL production while maintaining process efficiency.

- Turbo-Expander Focus: Robust designs that meet high-pressure, low-temperature separation needs crucial in cryogenic gas processing.

- Full Solution Provider: Our services include your total plant needs. From inlet compression through treating, dehydration, stabilization, product handling, and outlet compression, BCCK can supply completed turn-key facilities.

Cryo Gas Plant Projects

BCCK’s project experience includes GSP and RSV plants ranging from 60-225 MMSCFD facilities.

G2R-Flex™

Increased propane recovery in ethane rejection on existing GSP facilities, with our G2R-Flex retrofit technology.

CRYOGENIC GAS & TURBO EXPANDER PLANT SOLUTIONS

Read more about BCCK’s extensive experience in this arena.

FEATURED PROJECTS

- BCCK Boosts Propane Recovery with Next-Generation Technology at Cryogenic Gas Processing FacilityBCCK, a leader in engineering, procurement, fabrication and field construction services, has applied patent-pending technology, G2R-Flex™, to provide enhanced propane recovery for a premier midstream group in Ohio’s Marcellus-Utica Basin.… Read more: BCCK Boosts Propane Recovery with Next-Generation Technology at Cryogenic Gas Processing Facility

- BCCK Holding Company to Enhance Recoveries at Cryogenic Gas Facility in Marcellus-Utica BasinBCCK Holding Company has been awarded an EPC contract to improve overall project economics at a cryogenic gas facility in the Marcellus-Utica Basin, in southeastern Ohio, United States. Drawing upon… Read more: BCCK Holding Company to Enhance Recoveries at Cryogenic Gas Facility in Marcellus-Utica Basin

- BCCK Delivers New Cryogenic Gas Plant in North DakotaBCCK Holding Company (BCCK) has signed a contract with Outrigger Energy II, LLC (Outrigger) to deliver an ex works gas processing plant for the Bill Sanderson Gas Processing Facility in… Read more: BCCK Delivers New Cryogenic Gas Plant in North Dakota

Additional Technology Offerings

- NiTech® nitrogen rejection

- Helium recovery

- CO2 removal

- TEG dehydration

- Mole sieve dehydration

- Propane refrigeration

- Inlet gas chilling or dew point suppression

- Condensate separation/stabilization

- Flare systems

- Product storage

- Inlet separation and metering

- Compression

- NGL product fractionation

- MCCs and electrical power distribution

- PLC and DCS control systems