BCCK Utilizes Latest Nitrogen Rejection Technology with New Facility in West Texas

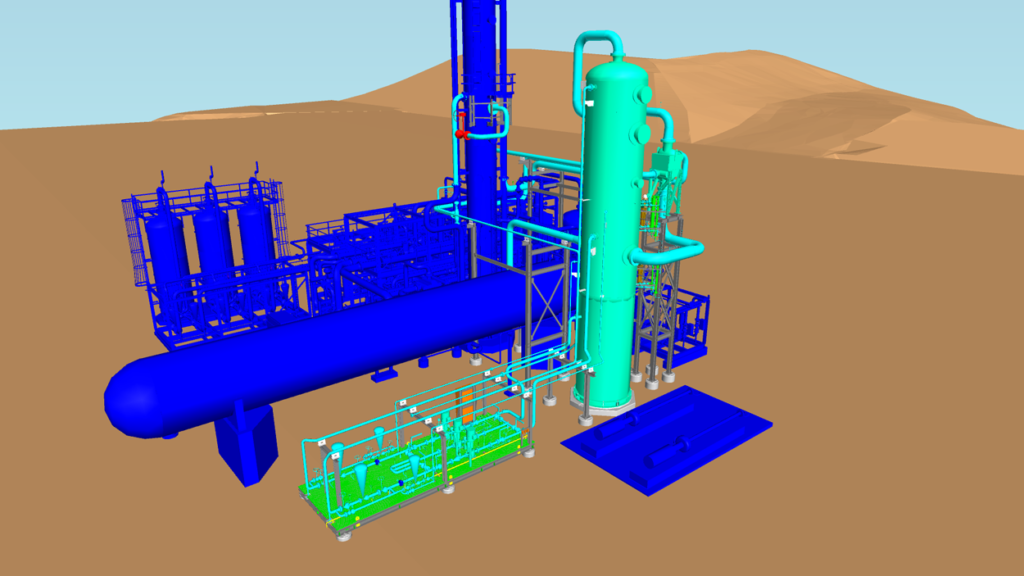

BCCK, a leader in engineering, procurement, fabrication and field construction services, has been selected to design and fabricate a NiTech® nitrogen rejection unit (NRU) facility in the Permian Basin.

The grassroots facility will utilize BCCK’s premier NiTech® NRU technology in West Texas. The project will use BCCK’s 220 MMSCFD NiTech® Style IV NRU designed optimally for plants operating in both ethane recovery and in rejection. The Style IV NRU features a modular skidded design resulting in a more economical installation. The Style IV is the company’s latest update and is capable of high recoveries for optimal efficiency and lower greenhouse emissions.

Greg Hall, executive vice president, BCCK, said, “We are excited for the opportunity to expand our reach in West Texas and demonstrate BCCK’s vast gas processing and nitrogen removal knowledge through our patented NiTech® NRU process.”

For more than 30 years, BCCK’s NiTech® NRU has delivered gas processing and NRU solutions.