ESG

BCCK considers its role in promoting positive environmental, social and governance practices a vital part of our corporate strategy. By focusing on improving sustainability, serving our community and providing a safe and engaging environment for our employees as we conduct our operations, BCCK will continue to provide exemplary service for its clients in a responsible and meaningful way.

SOCIAL IMPACT & COMMUNITY OUTREACH

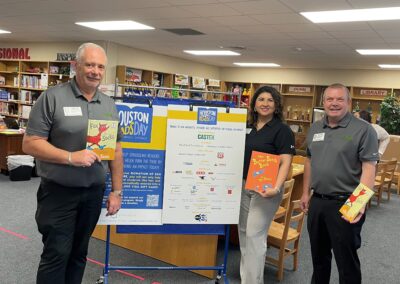

BCCK supports our communities through company-wide involvement in programs that allow our staff to grow, network and participate in charitable initiatives. Through BCCK’s volunteer program, our team members volunteer their time with organizations such as:

- Texas Ramp Project

- West Texas Food Bank

- Midland YMCA

- Kids’ Meals, Inc.

- Midland Baptist Crisis Center

- Honor Our Troops

- Annual Houston Reads Day

- Vitalant Blood Drives

Our involvement in various industry associations and events, such as GPA Midstream and the Coalition for Renewable Natural Gas (RNG Coalition), supports non-profit organizations that help provide scholarship programs and educational resources to students across the country.

EMPLOYEE ENGAGEMENT

BCCK is dedicated to making a positive impact within our team environment and within our community. Not only does BCCK sponsor volunteer days for our team, but the company also encourages collaboration and employee engagement through events like pickleball tournaments, frequent lunch and learns and seasonal activities such as holiday parties, family nights at local minor-league baseball games and quarterly company cookouts.

DIVERSITY & INCLUSION

BCCK values our team’s individual contributions and takes pride in our multicultural workforce. We are proud to offer a diverse and inclusive workplace with an ethnically diverse staff and numerous women in senior leadership roles. Forty percent of BCCK’s workforce is female, including our VP of Engineering and our Director of Project Management, as well as many of our engineering staff.

BCCK’s workforce includes employees from countries throughout the world, including England, Scotland, France, Poland, Brazil, Colombia, Spain, India and Vietnam.

INNOVATIVE ENVIRONMENTAL TECHNOLOGIES

BCCK provides leading technological solutions by designing and managing nitrogen rejection units with environmentally-friendly designs. BCCK aims to help our clients reduce their carbon footprint through these technologies that lower emissions and other renewable solutions such as treating and conditioning renewable natural gas, purifying Hydrogen gas coming off electrolysers (Green Hydrogen) and purifying captured CO₂ before sequestration. These solutions support BCCK’s customers in their emission reduction goals and serve as stepping-stones to exploring low carbon alternatives.

BCCK supports our clients in their operational goals to reduce Scope 1 and Scope 2 emissions by design, engineering, fabrication and installation of leading technology solutions such as:

- NiTech Nitrogen Rejection units separate Nitrogen from landfill gas, thereby producing Renewable Natural Gas (RNG), which serves as a valuable alternative to conventional fossil fuel-based natural gas and prevents the flaring of methane-rich landfill gas into the atmosphere.

- Hydrogen purification units produce pure Hydrogen, which is used to decarbonize hard-to-electrify sectors like cement and steel production, producing low-carbon ammonia, etc.

- Methanol to Hydrogen reformers reduce CO₂ emissions and fossil fuel use by creating Hydrogen and green methanol. These systems lower the cost of Hydrogen and simplify our clients’ energy transition needs while unlocking market potential in Hydrogen fueling, EV charging and microgrid applications.

- Clean-up for captured CO₂ post sequestration or other end-use prevents it from being emitted into the atmosphere and helps customers achieve their net-zero targets.

BCCK’s engineering solutions deliver key environmental benefits, operational efficiencies and cost savings. An in-house study was conducted to compare BCCK’s NiTech NRU and other competing technologies for a landfill gas project. It was found that NiTech NRU consumed approximately 65% less electricity than the competing technology, which equates to about 10,200 metric tons of CO₂ annually. This supplements the high methane recovery achieved by NiTech, corresponding to a whopping 94% reduction in the amount of methane that could’ve potentially entered the vent or converted to CO₂ before emission, thereby reducing the CI score of the project.